Recycling Scrap Metals: A Crucial Step Toward a Circular Economy

Metals like steel, aluminum, copper, and brass are all around us—think bridges, soda cans, wiring, and appliances. Unlike plastic or paper, metals can be recycled indefinitely without losing quality. Yet, tons of scrap metal still end up in landfills every year. In the U.S. alone, the scrap metal recycling industry processes over 130 million metric tons annually, but there’s still more sitting idle. Recycling these metals isn’t just about clearing junk—it’s about tapping into a resource goldmine that reduces the need to mine anew.

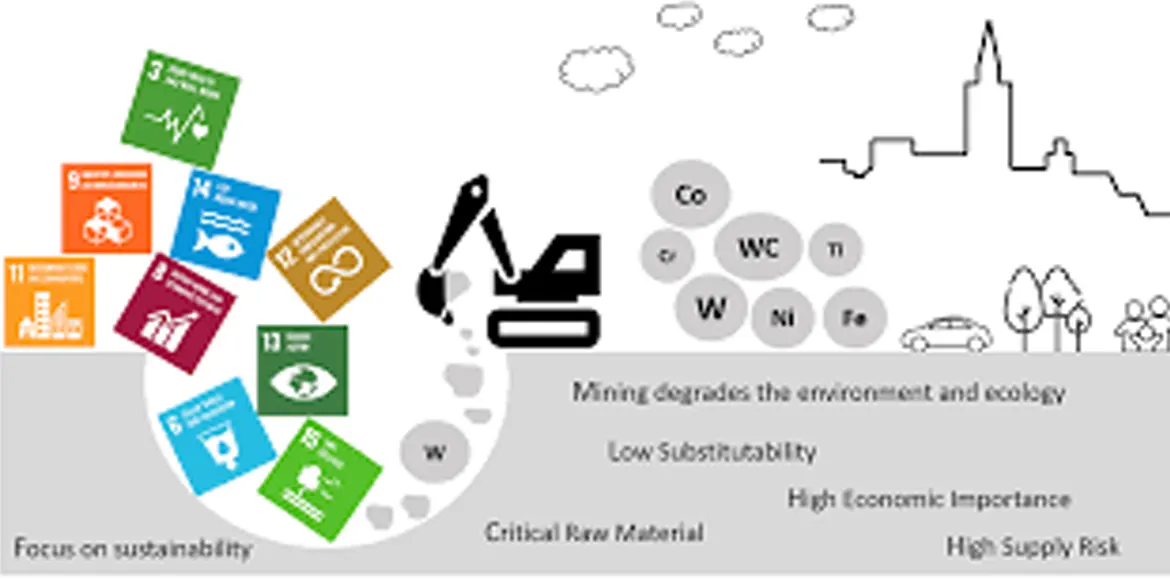

Mining virgin metals is a dirty, energy-hungry process. It scars landscapes, guzzles water, and pumps out greenhouse gases. Recycling scrap, on the other hand, slashes energy use—up to 95% for aluminum and 60% for steel compared to producing them from scratch. That’s a massive win for the planet and a key pillar of the circular economy, where we keep materials in use rather than tossing them out.

Recycling Scrap Metals: A Crucial Step Toward a Circular Economy

The world is buzzing about sustainability, and for good reason—our planet’s resources aren’t infinite. Enter the circular economy, a system where materials are reused and recycled endlessly, cutting waste and preserving what we’ve got. At the heart of this vision lies something surprisingly unglamorous yet incredibly vital: recycling scrap metals. From old car parts to rusty pipes, turning scrap into treasure isn’t just smart—it’s essential. Here’s why this practice is a game-changer for a sustainable future.

Kathryn Murphy

Reducing Waste and Risk

Beyond emissions, lead recycling tackles another industrial headache: hazardous waste. Unrecycled lead can leach into soil and water, posing environmental and health risks. By diverting batteries from landfills and safely reprocessing them, industries shrink their ecological footprint while meeting stricter regulations. It’s a double benefit—lower carbon emissions and a cleaner environment.